Abrasive Resistance & Wear Products.

Wear Conditions. We offer a range of WEAR products, for equipment and wear part solutions for mining and materials processing, with a dedication to engineering excellence, asset lifecycle management and reliable, down-to-earth support, which continues to deliver key improvements in mine and machine safety, productivity and performance.

ABRASIVE WEAR MATERIALS PRICING CATALOGUE - LINK

|

Laminated White Iron Wear Blocks - are a unique wear resistant materials, where they combine high wear resistant qualities of a high chrome cast iron ( 15/3CrMo, 700 BHN - 63HRc) with a weldable & high impact tough mild steel through a metallurgical bond, creating a product, exceptionally resistant to impact and abrasion. Extreme protection for extreme applications, chromium moly white iron, metallurgically bonded to a mild steel backing plate. With a nominal hardness of 700 Brinell (63Rc), the white iron casting provides maximum abrasion resistance. The mild steel backing plate is easily welded with minimal preparation, and acts as a cushion for the white iron - making it capable of handling impact and abrasion in even the most extreme applications. Available in numerous and varied shapes and sizes, Laminated white iron wear block products can be cut or bent to suit an application prior to welding to customise the protection on your machine or equipment. Custom parts may be designed to meet your exact specifications. |

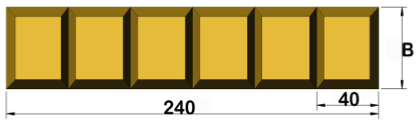

CHOCKY BARS - The unique design of Wear Chocky bars are available in various lengths, grades and sizes, may also be customised to the clients specific requirements. Applications for Chocky Bars are wide and varied, ranging from specific wear protection on buckets for loaders, excavators, drag line machines etc, for weld hammer tips for the recycling industry, chute linings and rock box edges. Easy to install, Chocky Bars can be bent, cut or formed to suit various surfaces. The standard thickness for Chocky Bars is 23mm, standard length is 240mm, width may be from 25mm to 150mm. Sizes may also be produced to meet special requests. |

|

Overlaying Wear Plate - Overlay wear plate is based on a "micro-carbide" system, which combines the improved wear resistance and impact resistance of the martensitic and chromium carbide deposits into the one plate. |

Wear Buttons / Donuts - Simple to use, no pre - or post heating when welding. Available in diameters from 60mm up to 150mm. Develop your own layout pattern to suit your particular wear protection solution. Dome & Flat Round Shaped:The perfect solution for ground engaging applications, such as, shovels, buckets, heavy earth moving equipment, etc. May be used in conjunction with Chocky bars, wear plates or individually to provide the toughest impact and wear abrasion circumstances.

|